With Kampol you will reduce your carbon footprint

Climate awareness is increasing around the globe and we also need to make a stance and show that we care. Our process ensures that pallets are reused, which not only substantially reduces CO22 emissions, but also saves the trees that would otherwise have to be harvested for new pallet production.

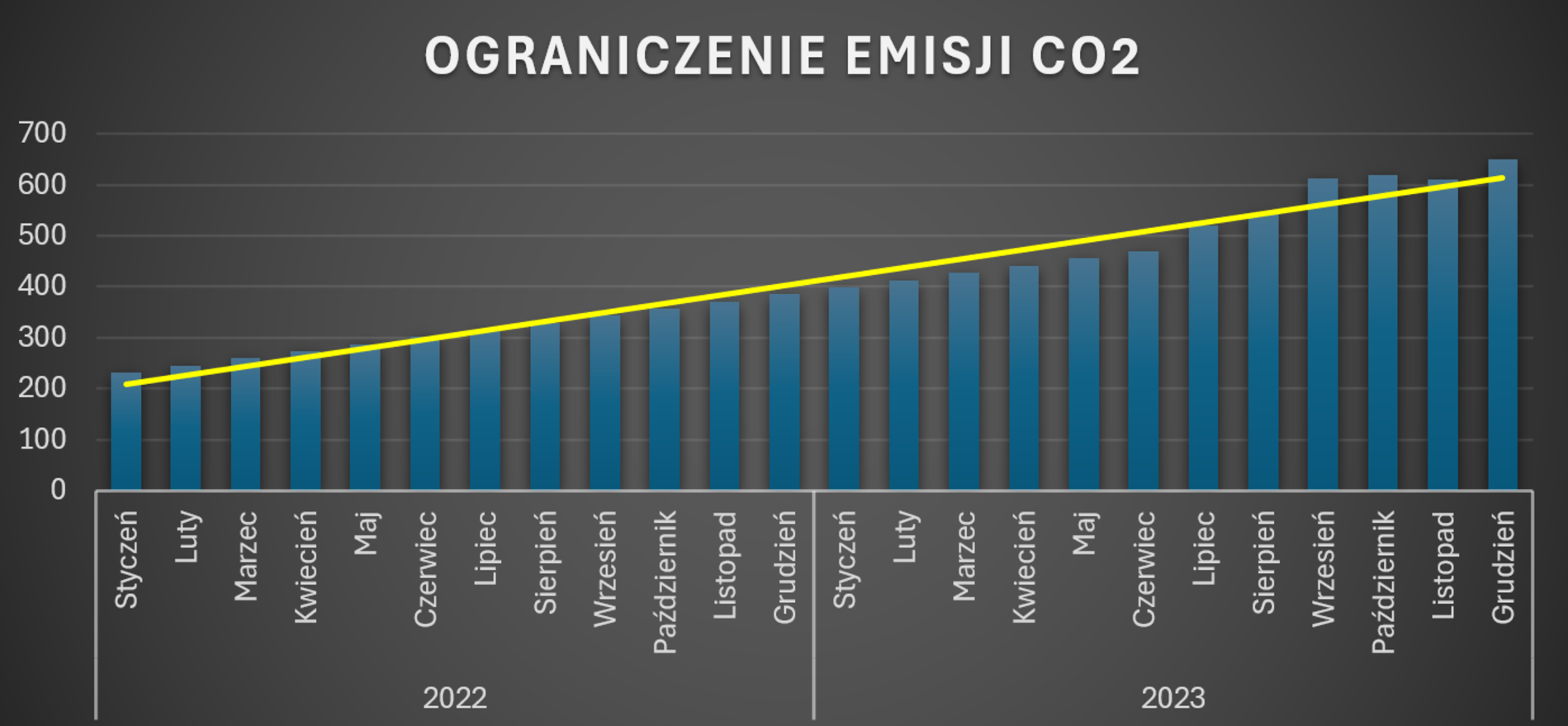

In 2022 and 2023 we reduced CO2 emissions by

9 856 491 kg

Carbon footprint

803,263 pallets were classified, or sorted, to be reused in 2022 and 2023, which reduced CO2 emissions by 3,310,908 kg.

Wooden pallets recycling also involves their repair for reuse. The values were reduced by the amount of CO2 needed to repair these pallets. 1,391,244 pallets were classified for reuse after repair, which reduced CO2 emissions by 6,545,583.04 kg.

In 2022 and 2023 total reduction in CO2 emissions was 9,856,491 kg = 9,856.491 tonnes.

Reduction in CO2 emissions by 9,856.491 tonnes equals to:

- the amount absorbed by approximately 469,357 trees per year.

- 4,195,235 litres of petrol burnt.

- CO2 emitted yearly by about 986 people.

- about 2,143 vehicles placed out of service per year.

- about 10,718,902 kWh electricity produced from coal.

These examples help to better understand the scale of CO2 reductions and demonstrate the real environmental impact.

Kampol Logistics is aware of and understands the need for reducing CO2 emissions, which is the key to environmental protection and achieving sustainable development goals. Our commitment to reducing CO2 emissions stems from the belief that environmental responsibility is not only a moral obligation, but also a strategic direction with long-term benefits for both our company and the global community.

Environmental decision

Environmental decision of reference number ŚiR.6233.07.06.2022, issued for Kampol Logistics, covers wooden packaging collection and repair – code 15 01 03, as part of the recycling process R12 – pallet repair.

Environmental decision issued for Kampol Logistics, also includes requirements for continuous monitoring of the company’s operations, to which the Regional Inspectorate of Environmental Protection (WIOŚ) has access. This means that the company is subject to regular inspections and control for compliance with environmental regulations.

Code R12: Refers to recycling processes in which waste is recovered and recycled without chemical treatment. In Kampol Logistics, the recovery and recycling process involves pallet repair.

What environmental benefits does this bring?

- Waste reduction: Pallet repair reduces the amount of wood waste disposed of in landfills.

- Resource-saving: Pallet reuse reduces the need for virgin wood.

- Environmental protection: The process promotes sustainable resource management and reduces negative environmental impacts.

The recycling process that is carried out in Kampol Logistics compliant with R12, includes the repair of wooden pallets, which contributes to resource efficiency, waste reduction and environmental protection. Compliance with the environmental decision and constant supervision by the Provincial Environmental Inspectorate ensures that the process is carried out in a responsible and compliant manner.